The concept of automation is nothing new and dates back to ancient times. Automated equipment has become an integral part of people’s everyday lives. It’s hard to imagine living without it, and we keep striving to progress in this field. Although we already have many automated machines, recently, attention has been directed towards all kinds of vehicles and machinery. Let’s look at the future of autonomous vehicles and devices in the coming years.

The rise of automation and autonomous vehicles

The history of early automation may date back as far as 4000 BC, and one of the earliest time measurement instruments – water clocks. They are documented to exist in the Middle East as well as Asia. Such devices typically transferred liquid from one container to another with time-calibrated markings, showing the day’s passage.

One of the most significant automation milestones we needed in 2020 was the contactless soap and sanitiser dispensers that made everyday lives a little safer during the most challenging months of the COVID-19 pandemic by limiting contact with surfaces in public or higher-traffic spaces.

With the rise of AI, machine learning, and technology development, automation has advanced significantly, giving us even more opportunities to relieve humans from doing tedious, repetitive tasks. Thanks to autonomous vacuuming robots and much more, computers and software help us perform complicated calculations and aid in everyday tasks like cleaning.

There is a five-level (six-level, if we include Level 0) scale that measures self-driving capabilities:

- Level 0 – No automation: the driver/operator performs all the tasks

- Level 1 – Driver assistance: the vehicle or machine assist with specific features like steering or acceleration-and-braking control under limited circumstances

- Level 2 – Partial automation: on this stage, the car or vehicle can help control speed and steering, spacing between cars and centring in lanes. An example is Tesla’s autopilot or Audi’s Traffic Jam Assist.

- Level 3 – Conditional automation: this level allows the AVs to control themselves in minimal, ideal conditions, for example, on a limited-access highway. A driver is still required behind the wheel, but they don’t need to control the vehicle unless necessary.

- Level 4 – High automation: highly-automated equipment and cars can drive without human interaction or intervention.

- Level 5 – Full automation: fully autonomous cars could drive themselves on known and unknown roads without human input under any road conditions. Hence they wouldn’t need human interaction. Their design would exclude steering wheels or pedals. General Motors hopes to deploy Cruise AV, a fully autonomous model, in the coming year

Emerging technologies and driverless cars

Autonomous vehicles and driverless vehicles are among the hottest in technology development today. Companies (especially in the US) currently use driverless cars for delivery. Driverless delivery vehicle maker Nuro partnered with, among others, Walmart and Domino’s Pizza for driverless delivery services that are currently in operation. Such vehicles don’t require a driver and use renewable energy to charge, which helps reduce CO2 emission levels for better sustainability.

Regarding proper cars we drive daily, these are not yet completely automated and driverless, although we strive to get there. Cars like Tesla offers advanced assistance. However, they still require a driver to stay alert to ensure no error occurs constantly and nobody gets hurt. Driverless vehicles and machines are essential for everyday transport and can also be a game-changer in the industrial sector, especially regarding autonomous construction equipment.

Examples of autonomous vehicles

Delivery cars: these work primarily in the US for chains like Walmart or Domino’s Pizza. They use sensors and built-in technology to deliver customers’ orders. Customers can place their orders online and use an app to track them. The customer will receive a security code when the vehicle arrives. Then they must enter the security code on the mounted touchscreen to open the cargo compartments and pick up the goods.

Driverless cars: we haven’t yet arrived at the stage of fully autonomous vehicles. They need one operator, specifically a driver, to be always present to ensure safety. However, certain levels of higher independent level (for example, in Tesla cars) allow the vehicle to drive independently, using its technology and sensors, under careful supervision.

Heavy equipment: heavy machinery in construction and other sectors will be precious. The technology will allow working on sites that could harm the human crew. This way, the remote control would enable remotely controlled vehicles even from miles away. Thus, contractors would be able to work on sites from all over the world.

Current solutions for autonomous vehicle technology

Nowadays, automation seems obvious, an integral part of everyday life. It’s present in every aspect, whether our day-to-day activities, science or business. Different solutions are already implemented and continuously developed. Some of the critical sectors in which autonomous machinery can have the broadest prospects include:

- Autonomous driving

- Space exploration

- Autonomous construction machinery and heavy equipment

- Military

- Public transport

Autonomous driving

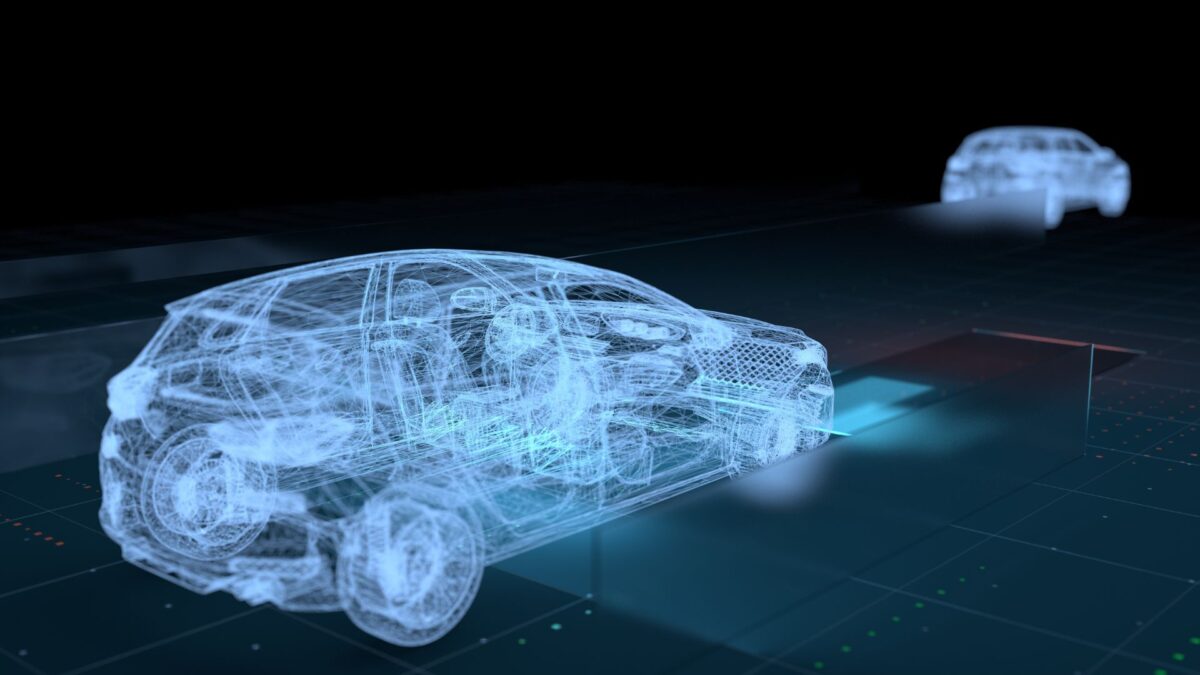

Ultimately fully autonomous driving for regular cars is not yet a thing, as it is a challenging endeavour where we still require human supervision to ensure safety in everyday traffic. However, modern-day semi-autonomous vehicles offer a wide range of options for driver assistance that helps reduce the chance of human error. Advanced Driver Assistance Systems (ADAS) are autonomous systems that, among others, include:

- Collision avoidance system

- Pedestrian detection

- Lane departure warning system (LDW)

- Blindspot detection

- Driver drowsiness detection

- Parking assistance

- Adaptive headlights

- Lane-keeping assist (LKA)

- Traffic sign recognition

- Adaptive cruise control (ACC)

- Rear cross traffic alert (RCTA)

Although these systems don’t replace the driver entirely, they can significantly contribute to safety by helping drivers to stay safe on the road. Tesla cars can be equipped with autopilot or even fully self-driving capability that, while still in need of supervision, can have the car drive on its own.

Space exploration

A prime example of an autonomous vehicle would be the Curiosity rover, developed by NASA for Mars Science Laboratory (MSL) mission. Its primary goal was to help assess whether Mars could ever have supported life, determine the role of water and study the climate and geology of Mars. Equipped with state-of-the-art technology, the rover is still operational as of the 5th of February, 2023. Launched on the 26th of November 2011, it landed on Mars on the 6th of August 2012. Since then, it has collected and transferred data for continuous research for over a decade.

Space exploration and Earth observation are necessary for developing autonomous vehicles and crewless machinery. It can enable us to reach places where people can’t go. There are already many crewless vehicles in space that help in research and monitoring.

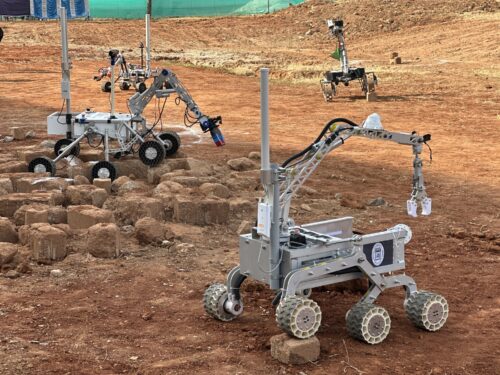

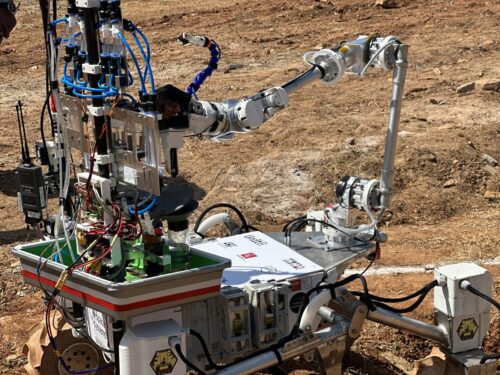

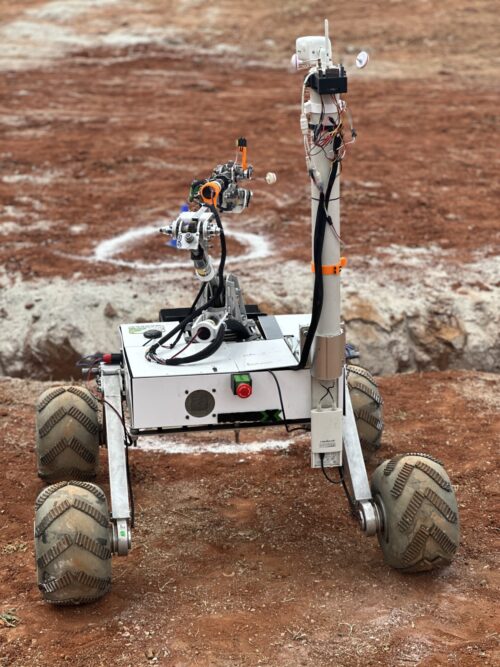

International Rover Challenge (IRC) 2023

At DAC.digital, we got an insight into the area of autonomous vehicles for space exploration. Our Head of Community – Justyna Pelc, had an opportunity to be the head judge at International Rover Challenge 2023. She traveled to India together with Natalia Paprota, our Head of Marketing. Natalia joined the competition as a guest judge and had a chance to assess the business appeal of the respective challenges and teams. This opportunity came with Innspace – a group created and co-founded by Justyna and her fellow space exploration enthusiast.

IRC is an annual robotics competition with an engineering challenge to engage students worldwide in the next phase of space exploration. It aims to encourage the spirit of innovation amongst budding engineers as they build space exploration rovers using their skills and ideas.

The teams must create a report and a video of their rovers, displaying their capabilities. Later on, the best teams are selected for the finals. The final competition takes place on a field designed to imitate the barren surface of Mars and comprises four tasks that simulate the actual work on the surface of the Red Planet:

- Extreme Retrieval and Delivery – moving around on challenging terrain with rocks, steep slopes, obstacles, and sandy areas to locate and retrieve items and deliver them to a specific location.

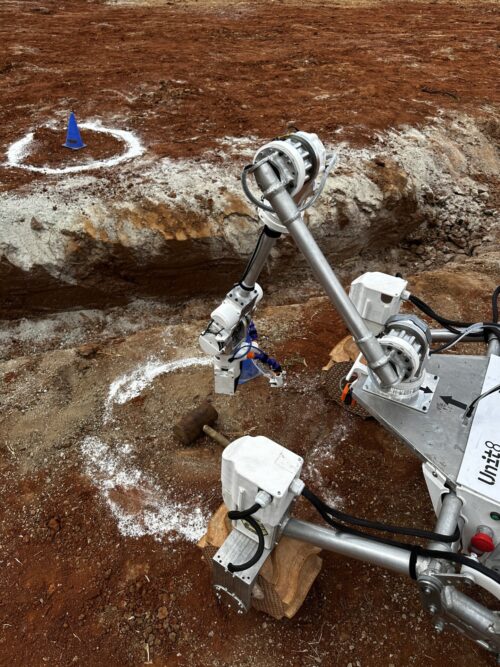

- Equipment Servicing – this challenge tested the rovers’ capability of performing dextrous operations on the control panel and maintenance work to see if they were prepared for the intricate work in the field.

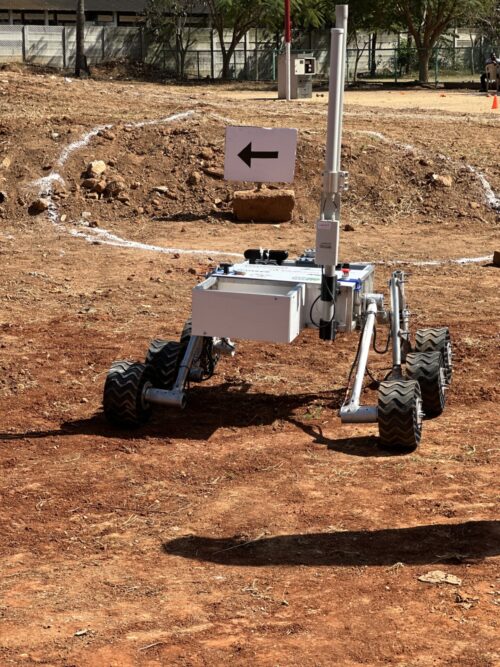

- Autonomous – this task required the rovers to autonomously traverse the field through designated gates with marked directions on the field without remote control and human intervention to ensure it could do well on Mars.

- Science Cache – the primary goal of the Science Cache Task is to conduct an in-situ analysis of soil samples on the rover to determine the possible existence of life on Mars. Rovers must dig and collect soil from designated areas, obtain a microscopic view of rock samples, and collect panoramic images of the surroundings in this mission. The rover also conducts tests to check the presence of life-supporting gases.

This year, the team from Poland, AGH Space Systems, emerged victorious in the competition that took place in Bangalore, beating the other 17 finalists. Thus, they repeated their success from IRC 2020.

Adam Zagrajek – AGH Space Systems Team Captain for IRC 2023:

“Competing in IRC has taught us many things. For example, building an autonomous mobile robot requires cooperation between engineers from various fields. Developments in autonomous offroad navigation are not limited to software – we can, for example, use 4 independently turning wheels of our rover to drive sideways or turn in place. We see students developing solutions that are not readily available. In our case that is a custom path-follower leveraging 4 independent wheels, a slope-sensitive cost map, or shell-over-radio communication. In this way, IRC allows students not only to learn, but also contribute to the field of autonomous robots.”

Construction industry

Automation in dangerous construction sites

Autonomous construction can likely be one of those industries that could use autonomous equipment the most. Construction sites must face various challenges, including multiple dangers construction projects may bring. A construction site can also hide potential dangers, such as landslides or unstable ground. Altogether, it may be unsafe for humans to operate construction equipment. Construction sites also make it impossible for humans to work, as they may pose a toxic hazard. In such cases, construction companies could use semi-autonomous heavy equipment, using automation and remote control in their construction process.

The future of autonomous construction equipment

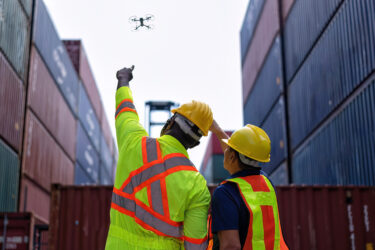

The construction industry may be a promised land for innovation and progress. An autonomous vehicle that could carry out the construction in environments where humans wouldn’t be safe could be groundbreaking not only in the construction industry but also for other purposes, for example, off-road rescue operations after environmental disasters, where the site cannot be deemed as safe with certainty. However, working in hazardous environments can be challenging for crewless and driverless machines. Here’s an insight from experts, regarding drones:

“(…) The blades could generate static electricity and therefore cause a spark. Which could form a source of ignition in a hazardous area and cause an explosion. Of course, a hazardous area design could overcome this issue amongst others so the drone can never form a source of ignition in the potentially explosive atmosphere. (…)“

– Sander van Tienhoven: Ex-Machinery Explosion Proof Equipment B.V. (atex air conditioning) – Commercial Director, co-founder of Cobic-Ex and Armadex

“(…) For example, we use drones for safety inspections of structures such as bridges, wind turbine blades and power lines, which can be difficult and dangerous for human inspectors to access. With high-resolution cameras and video, drones can help identify potential safety hazards and prevent accidents. (…)“

– Siarhei Palishchuk: Survey Engineer and CEO of DronesAlgo

Our own Bart Andrzejewski had a chance to become an excavator operator during the CES expo in Las Vegas. He remotely operated an excavator physically located in Illinois, 1678 miles from his position. The state-of-the-art technology presented by Caterpillar Inc. allowed the remote control with only as little as 100ms latency. Such solutions can make a considerable contribution to safety on construction sites.

Production industry

Like in construction, autonomous vehicles will become an essential part of the production work. Devices like an autonomous load carrier can significantly improve the production or warehouse operations workflow and efficiency by allowing the human workforce to focus on more essential tasks that cannot yet be automated or carried out without supervision.

Military

Driverless vehicles will have a tremendous impact on military operations. Ground and aviation vehicles that wouldn’t need a human operator can vastly increase safety and reduce human deaths during a potential conflict. It can also allow surveying the field and assessing the potential danger for human troops.

Automated flying machines and robots can also improve area surveillance, leaving people to perform more critical tasks. However, the challenges in the automation field indicate that fully autonomous units will not be achievable shortly. However, technological advancement and further research will change how an army fights and wins.

Public transport

Once vehicle automation progresses significantly enough to allow for complete autonomy, it can be invaluable for public transport. After thorough testing and safety measurements, the transportation fleet could be enhanced with autonomous solutions. However, before that happens, we would need to ensure that those vehicles working autonomously meet the requirements and regulations yet to be determined.

Technologies necessary for building safe and reliable autonomous vehicles

There will be no way to construct and deploy new machines with the autonomous operation if we don’t delve deeper into the existing and new technologies essential for this process. Certain technologies make the critical foundation for automation processes.

Machine Learning

To be completely autonomous, the vehicles need to perform many tasks. They include detecting and omitting obstacles, following traffic rules, and making decisions in changing and unexpected conditions. These tasks pose unique challenges that the machine learning system must address.

Therefore, engineers must interconnect and understand different machine learning systems to create the optimal combination for their specific purpose. It may be tedious because each system is designed for a particular task and may use different data formats and standards. Without it, however, full automation wouldn’t be possible. While each task is essential, the real challenge lies in building a system that can understand and use data from all tasks.

Creating a solid system to perform tasks like detection (of the car’s position, pedestrians, traffic signs and lights, and road marking), parking and maintaining cybersecurity is essential to achieve full automation. The role of machine learning is to ensure that the vehicle’s system can learn from data and make predictions about the world around it.

Artificial Intelligence

AI goes hand in hand with machine learning in building efficient systems for driverless vehicles. It can help automate repetitive tasks and enhance built-in features the same way ML algorithms perform them. Artificial Intelligence and ML-based object detection algorithms can collect data, analyse objects, and make accurate decisions while on the road. Intelligent machines can also solve problems occurring in advance by predicting events through quickly processing data.

“(…) The use of AI techniques, such as machine learning and computer vision, has allowed machines to perceive their environment and make decisions based on that information. By collecting data on factors such as temperature, humidity, and air quality, for example, we can better understand how these variables impact worker safety and adjust working conditions accordingly. This approach provides critical insights that can be used to improve the safety and efficiency of work in dangerous environments. (…)“

– Iu Ayala: Gradient Insight Ltd

AI-enhanced features would include personal AI assistants, radar detectors, and cameras, which prioritise security, among other functions. Implementing AI enhancements would indicate a significant advancement in comparison to their predecessors. A self-driving car can learn about the driver’s traits, like speed, preferred car temperature, driving mood, observance of traffic signs, songs they enjoy the most or favourite radio stations. By rating driving skills, these autonomous vehicles have helped to change destructive driving behaviours and habits.

Internet of Things (IoT)

IoT implementation can enhance safety through, for example, intelligent networks in the city. Thus, autonomous vehicles could connect to the city networks to ensure better road safety and assess specific issues that may appear, including traffic jams and road accidents, to plan an alternative, more optimal route.

IoT can also be implemented to connect different devices to the vehicle for added features and apps to ensure a better driving experience or control of the car and its tasks. The vehicle could import settings and items from external devices to help plan routes, control the ambient (e.g. music) and access the maps and pre-programmed routes or entire journey plans.

The Industrial Internet of Things (IIoT) can help connect vehicles used in manufacturing and industrial processes. Connected sensors and actuators enable companies to identify inefficiencies and problems sooner and save time and money while supporting business intelligence efforts. It can help enhance communication between the connected devices for better control and safety. It may significantly improve the workflow in the industry.

Future gamechanger

The development of autonomous vehicles will undoubtedly make a game-changing element of future life and projects in different industries. Operators can focus on more strategic aspects of projects while allowing the machine to run the operation independently. One may think that fully autonomous vehicles are long overdue. However, there are many challenges the technology faces, and some of them, like safety, can never be left to chance.

Although there are still some technology milestones to reach before enjoying a relaxing drive while the car does the job, the prospects are pretty promising. The progress in developing autonomous construction equipment can genuinely contribute to the entire industry.

If you want to discuss the solutions further, please reach out. We’ll be happy to share our expertise and experience in the field.

Katarzyna Świątek

Junior Content Specialist at DAC.digital