Continuous information exchange can improve supply chain management. It enables to reduce the need for human intervention in case of sudden, unforeseen circumstances. The IoT technology allows for more precise tracking of shipments, monitoring of surrounding conditions, and more efficient fleet management. Check out how the Internet of Things is transforming logistics.

Today, we’re going to examine how IoT can benefit companies’ supply chains and get better value and efficiency through leveraging IoT in logistics. From improving tracking systems and monitoring product quality, through giving customers more choices, to monitoring what happens to a product after it has been purchased by a customer, we analyze everything! Additionally, we will investigate how all this information can contribute to enhancing the customer experience.

What are the problems IoT is facing in logistics?

The rapid growth of processes in some companies has resulted in tools for each phase of the process – as a result, companies now have many tools that can bog down employees’ work, or even subsequent stages. By integrating such systems, time can be saved, and process efficiency can be increased – but the challenge of integration is yet to be faced by many.

It is even an obligation in the logistics field to monitor and anticipate changes that may take place. Changing trends have led to an expansion of tasks in this area, as well as dynamism and complexity of processes that have been growing. Additionally, it influences which tools and techniques are best suited to managing them. The IoT concept for these companies seems an ideal solution, given the volume of transported or stored goods that require constant monitoring.

How can the Internet of Things help logistics?

Logistics and transportation are undoubtedly industry segments that will be significantly impacted by IoT solutions. Every day, millions of goods are stored, monitored, and transported. There are many people involved, as well as vehicles, IoT devices, and tools specially designed to accomplish the work.

Using IoT in logistics and transportation allows the integration of various assets within the supply chain and the subsequent analysis of the data generated by these connections. In turn, this improves the efficiency of warehouse logistics, delivery management, and fleet management in every logistics company today.

Let’s take a look at all the advantages.

#1 Optimization at its finest

A logistics company must not only cost-effectively manage its time, but also save money. Target customers in this industry tend to want even faster and cheaper deliveries. With consumers approaching logistics companies in this manner, there is a lot of pressure on logistics companies to adapt to the current needs of customers. This might sound intimidating, but the Internet of Things concept meets the needs of the industry perfectly, allowing it to optimize in the most critical areas.

As a result of using connected technologies, logistics companies can reduce costs, improve service levels, optimize fleet management, and reduce manual actions (which can significantly delay the process).

Aside from the fact that IoT can have a positive effect on the company itself, there are other benefits to its operations as well. Regular employees, for example, may also benefit from the optimization process, as they are given real-time information about traffic volumes (to prevent downtime), and weather – which will in turn result in savings on gasoline.

It allows for continuous information sharing, tracking goods, reducing downtime – which is usually expensive – and managing fleets.

All for the sake of optimization.

#2 Access to data not available anywhere else

By analyzing big data, companies can gain valuable insights into the location and condition of their goods. This information previously was not available to them! Data from this source is useful not only because it is able to help supply chain managers with real-time problems, but also because it is used to enable extensive optimization.

Firstly, managers are able to make informed decisions that improve not just a single box, but the entire supply chain operation when they understand the context and root cause of problems. A manager may discover that certain routes are much more prone to experiencing delays or mismanagement after analyzing a particular shipment.

Also, the manager can easily resolve the issue in the future by simply changing the route and saving money and time on subsequent shipments. Such information can have a lasting impact on a company’s bottom line, as it enables managers to not only solve the problem in real-time, but also understand and eliminate the root cause of the problem. Using IoT, companies can optimize their supply chains from start to finish and make decisions based on data, not guesswork.

#3 Real-time error detection, reaction, and reduction

IoT systems in supply chains include distributed sensors that track location and status of goods in transit and transmit data in real-time to the cloud. The online platform gives managers access to and interaction with GPS coordinates, as well as the data collected by sensors, which keeps managers up-to-date about shipments. Managers can access important information using the digital supply chain, and take immediate action if a problem arises.

In some cases, IoT trackers can send real-time alerts if temperature-sensitive products reach harmful temperatures, allowing the sender to fix the problem before damaging the product. If this information is available in real-time, the company can potentially avoid costly damages or delays.

#4 Increasing the efficiency of industrial processes

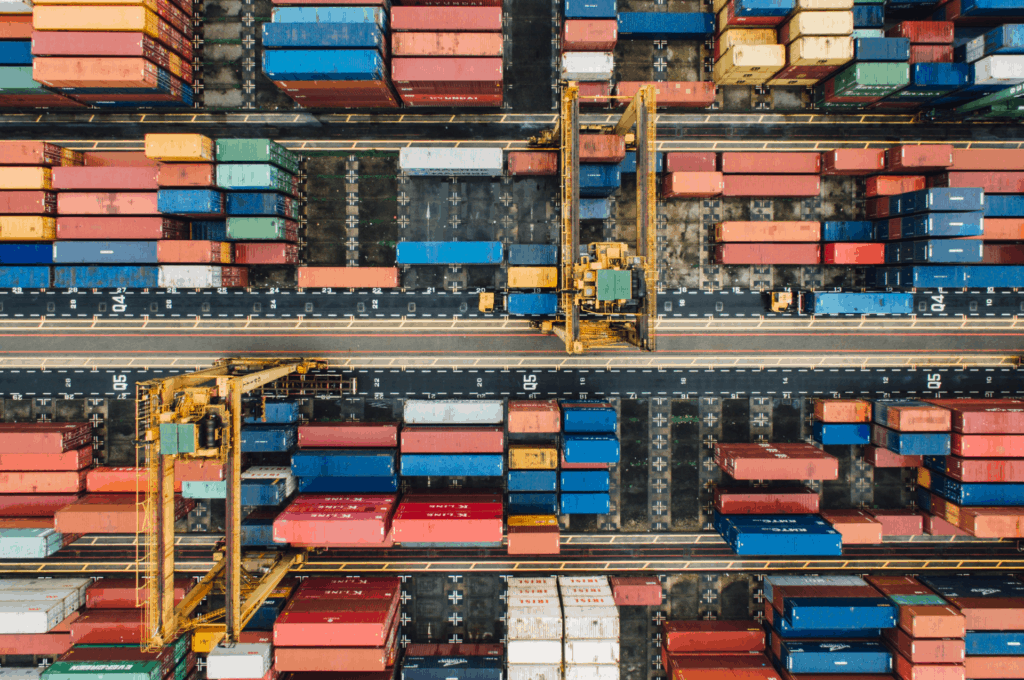

Supply chain efficiency and reliability can be improved with visibility, and IoT tools provide companies with visibility across the supply chain. It can take weeks or even months for shipments to pass through many global supply chains. Goods in transit often present significant unknown variables, which cause widespread inefficiencies and waste. The use of Internet of things tools, however, helps managers gain insight into their goods and processes in order to shed light on potential dark spots in their supply chains.

In the past, managers relied solely on loggers and other passive tools that provided data afterward, without context or real-time notifications. Digital supply chains powered by IoT provide real-time location and condition data directly from the cloud. It allows users to avoid problems before they arise and avoid unnecessary waste. By forecasting accurate arrival times and replacing damaged or delayed goods, managers can identify supply chain issues and optimize them.

Supply chain managers will experience fewer unpleasant surprises with improved performance. They gain insight into the full picture and find problems as soon as they arise. Long story short: managers can improve large-scale inefficiencies by using an IoT-based digital supply chain.

#5 Providing better customer experience

Consumer expectations are rising across all industries as businesses strive to provide rapid on-demand services. As consumers demand more and more precision and quality from the products they buy. That is why many shippers are struggling to keep up. It is only through the development of IoT-based digital supply chains that manufacturers will be able to compete in this new environment.

Managers can alert their customers in advance if a product is being shipped early, late, or damaged if they have real-time insight into transport crates and goods in transit. It is even possible for managers to use this warning to quickly fix the issue before customers discover it. Using Internet of Things tools, managers can provide their customers with the best level of customer service possible. What is even more, they can enable them to be more satisfied with less effort.

The best IoT use cases in logistics

#1 Optimization of warehouses and transportation

A flexible supply chain begins with a warehouse that functions efficiently. The improvement of their operations can significantly reduce operating costs. An IoT-enabled warehouse allows a holistic view of its operation. Here are just a few examples: temperature, condition of the stock, and operation of the devices. The company can then analyze the processes in their entirety and make appropriate corrections using these data. It is possible to monitor only humidity levels and temperature during storage. Moreover, you can chceck also any issues that occur during transportation with today’s technology.

Innovative devices contribute to success. By using intelligent pallets and shelves, it is especially beneficial in managing warehouse space. In addition to helping the transportation of goods, sensors in cars record cargo movement more precisely, predictably, and safely than before. As well as overseeing the transport of dangerous or delicate products, they ensure properly storing of goods.

A technological solution also aims to minimize equipment failures and streamline the supply chain by automatically planning activities. Internet of things will also affect the organization of transport. It includes, for example, booking places at charging stations for electric vehicles, automatic tolls in congested areas, or self-diagnosis. An Internet of Things system can provide a central place to control employees and.

#2 Anti-theft protection in the logistics industry

An IoT solution can provide security measures such as alarms and video surveillance to protect equipment and inventory against theft. These systems collect data needed to determine which areas need additional security and strengthen them accordingly.

#3 IoT-enabled delivery tracking

In the past, shipping tracking required the scanning of product barcodes at various stages of delivery. Nowadays, companies use RFID tags linked to cloud storage in more and more cases. Thanks to that, employees can focus on performing only one task: loading goods.

A logistics company’s ability to deliver on time makes or breaks them today. Using GPS technology, IoT can minimize delays in transportation resulting from unfavorable weather conditions or poor road conditions. This provides drivers with the opportunity to take action to prevent delivery delays by continuously informing them of possible difficulties.

#4 Employee security and monitoring

Having sensors installed in internal transport enables monitoring for their technical condition, preventing accidents during use.

By using IoT, businesses can analyze and develop their human resources. By assessing which drivers are most effective, employers can easily identify skill gaps. Thus, training current and future employees becomes easier, increasing the efficiency of their work.

What is the future of IoT in the logistics industry?

There’s still more to come! An IoT-based digital supply chain can generate an enormous amount of data that manufacturers have only begun to understand. In the coming years, Internet of Things tools will become more spread out. More data will become available, enabling companies to leverage advanced predictive analytics tools to make use of these datasets. It can help managers look for patterns in data that already exist. Moreover, it will help also to go a step further by predicting problems in the future based on historical data.

Technological improvements in cellular networks and long-term tracking technologies will boost the effectiveness and efficiency of IoT-based digital supply chain solutions.

Exciting times ahead!