The begin of the journey

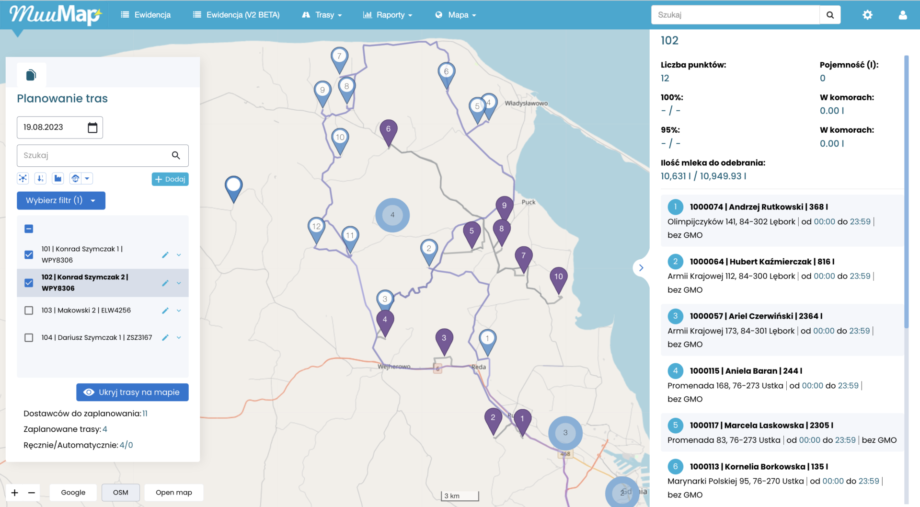

- It all started with a navigation tool for the drivers. The client noticed that new drivers faced challenges navigating through the 3000 dairy farms. They needed details about accessing area premises, locating milk tanks, and gate openings. Typically, new drivers spent two months riding along with experienced drivers to learn the routes, and even then, they would call dispatchers or other drivers for directions to specific farms.

- To address this, we collaborated with the client and developed a solution. We placed location pins on the map for each farm’s milk cooling station and, if needed, “drew” a new road. This helped drivers get precise route plans, accurate directions, and essential information about the yards they visited.

- The success of this application reduced driver training time from two months to just 2-3 days.

- Later, the Manager module was created, serving as a massive CRM system. It holds vast amounts of information about farmers, their milk deliveries, drivers, license expiration dates, available fleet, subcontractors, destination points, and daily production demand. This comprehensive tool provides an all-encompassing overview of the entire dairy operation.