During the last week of November, partners of the Productive4.0 project met in Bilbao to present the current achievements and to work on future challenges in digitalizing the European industry. Partners were discussing the future of the digital industry.

The aim of Productive4.0 is to create a user platform across value chains and industries thus promoting the digital networking of manufacturing companies, production machines, and products. The project addresses the current trend of automation and data-driven manufacturing in Industry 4.0, commonly referred to as the fourth industrial revolution.

DAC.digital involvement in the Productive4.0 consortium

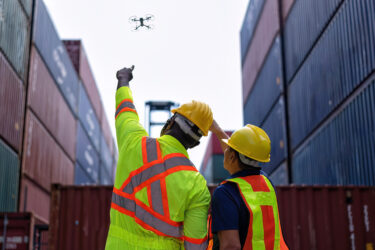

DAC.digital, as a member of the Productive4.0 consortium, works on solutions to increase the transparency of the supply chain and improve the visibility of transported products and components. As a result, our company develops a decentralized data exchange environment enabling information flow in product lifecycle and supply chain management systems thanks to distributed data space architecture.

A real-life example of this approach is Digital Product Footprint, implemented jointly with Thales Netherlands. It integrates distributed PLM systems, operated by different parties in a multi-stakeholder ecosystem. The aim is to furnish visibility of product and component dependencies across the value chain. DPF supports the bidding process, product configuration, and change management. It is possible by encompassing all data items relevant for managing all aspects of a product.

About Productive4.0

109 partners from 19 countries work together in this consortium. They will examine methods, concepts, and technologies for service-oriented architecture and electronic components for the Industrial Internet of Things. Therefore all partners will work on creating the capability to efficiently design and integrate hardware and software of IoT devices. Other aspects are standardization and process virtualization, in other words, simulating manufacturing processes to optimize real workflows.

The platform can be used in the three interlocked process pillars for managing the supply chains, the product lifecycle, and digital production. For more details visit the official Productive 4.0 website.